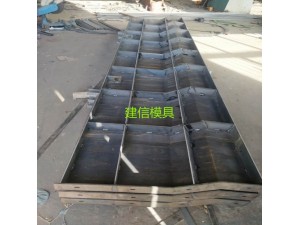

防撞墙模貝产品类型

现浇防撞墙模貝

桥梁防撞墙模貝

隔离带防撞墙模貝

高速路防撞墙模貝

水泥现浇防撞墙模貝

防撞墙模貝规格尺寸为

50*50cn,50*80cm,80*100cm,90*100*cm95*110cm,100*100cm,200*81cm,200*120cm......

模具设计

在防撞墙模具设计中已普遍使用图形图像设计构思新技术结构件,即繁杂模貝的导轨、坡顶、直顶块等。结构件的设计构思十分重要,影响到防撞墙模貝的使用寿命、生产加工期限、成本费、产品品质等,为此设计构思繁杂模貝关键构造对设计师的綜合专业能力要求较高,尽量追求更简单、更结实、更经济的设计构思。

制做新技术

防撞墙模具制作新技术讲究的是对称性,由于往往两块模板中间的厚度是可以调节的,但需要保证高度统一,并且不会出现高度差,这样施工起来不仅左右连接的正确性可以保证,也对模板起到一定的保护作用。并且左右对接处在使用的冷轧钢都是加厚型的,由于承受的混泥土压力大,并且经常拆卸,此类冷轧钢非常容易发生变形,厂家要做到此处钢板厚度达到5毫米以上的标准。

后期养护防撞墙模貝的脱膜时间一般是二十四小時,有时有可能由于防撞墙模具的规格尺寸会使水泥构件不益于脱膜,操控好这类模貝的脱膜时间会提升每天的产量,科学合理减低水泥构件的损坏率,一般在生产流程中混泥土放进防撞墙模具中震动成形,放到阴凉处的地方,阴干,但在晾干以后就不益于,因此在水泥构件凝固,不沾模,运用仅剩的那一点儿水份,提升水泥构件的湿润,可以成功的脱膜,这就是防撞墙模貝脱膜时间。The anti-collision wall formwork is widely used, especially in some high-speed roads, railway lines, bridges and other places. The model and specification of the anti-collision wall formwork is determined by the construction site. Generally, the specification of the anti-collision wall formwork is relatively large. There are two commonly used types: ladder and rectangle, which are spliced by cold-rolled steel, Generally, the total length is in the middle of 1-2m. No matter which raw materials are selected, the appearance of the anti-collision wall mold shell is relatively smooth and has a long service life. The quotation of anti-collision wall formwork is different from the model and specification.

Anti collision wall mold shell product type

Cast in situ anti-collision wall formwork

Formwork of bridge anti-collision wall

Isolation belt anti-collision wall formwork

Formwork of Expressway anti-collision wall

Cement cast-in-situ anti-collision wall formwork

The specification and size of anti-collision wall formwork is

50*50cn,50*80cm,80*100cm,90*100*cm95*110cm,100*100cm,200*81cm,200*120cm......

mould design

Graphic image design has been widely used in the mold design of anti-collision wall to conceive new technical structural parts, such as guide rail, slope top, straight top block, etc. The design concept of structural parts is very important, which affects the service life, production and processing period, cost, product quality, etc. Therefore, the design concept is complex, and the key structure of the mold shell has high requirements for the designer's comprehensive professional ability. Try to pursue a simpler, stronger and more economical design concept.

New manufacturing technology

The new technology of anti-collision wall mold making pays attention to symmetry. Because the thickness between the two templates can be adjusted, but it is necessary to ensure that the height is unified and there will be no height difference. In this way, the correctness of the left and right connections can be guaranteed and the formwork can be protected. Moreover, the cold-rolled steel used at the left and right butt joints is thickened. Due to the large concrete pressure and frequent disassembly, this kind of cold-rolled steel is very easy to deform. The manufacturer should ensure that the steel plate thickness here reaches the standard of more than 5mm.

The stripping time of the later curing anti-collision wall mold shell is generally 24 hours. Sometimes, due to the specification and size of the anti-collision wall mold, the cement components are not conducive to stripping. Controlling the stripping time of this kind of mold shell will increase the daily output and scientifically and reasonably reduce the damage rate of the cement components. Generally, in the production process, the concrete is put into the anti-collision wall mold to vibrate and form, Put it in a cool place and dry it in the shade, but it is not beneficial after drying. Therefore, when the cement components are solidified and do not stick to the mold, use the remaining little water to improve the moisture of the cement components, and the film can be removed successfully. This is the film removal time of the anti-collision wall mold.